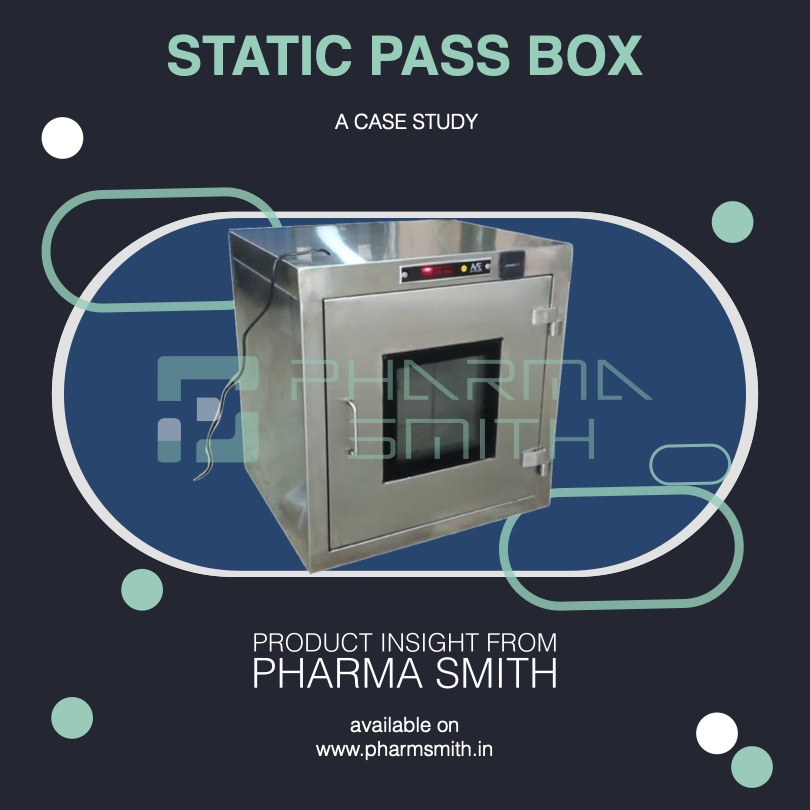

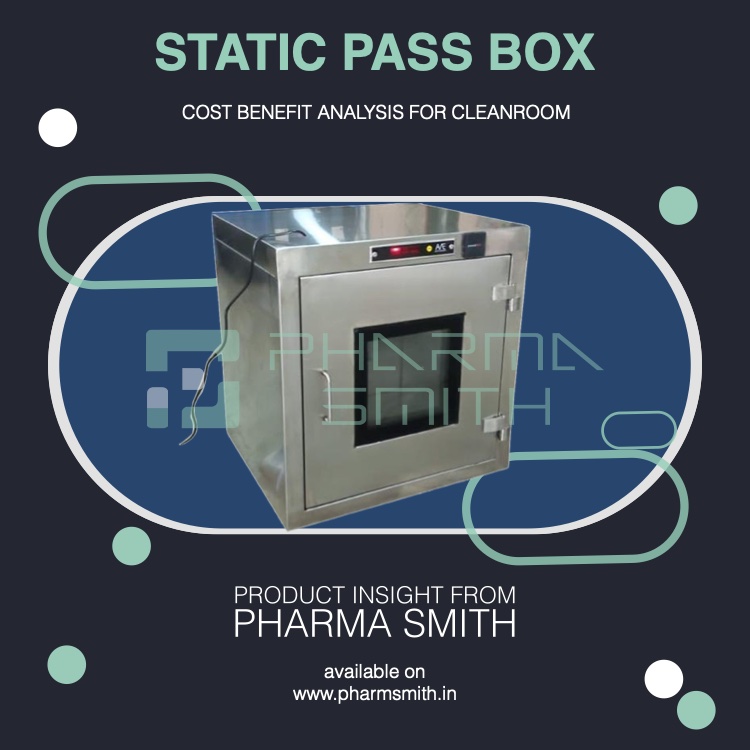

Maintenance Tips for Your Static Pass Box (Pharmaceutical & Food Processing Guide)

Maintenance Tips for Your Static Pass Box (Pharmaceutical & Food Processing Guide) In pharmaceutical and food processing facilities, contamination during […]

Maintenance Tips for Your Static Pass Box (Pharmaceutical & Food Processing Guide) Read More »

Uncategorized